Have you ever wondered what goes into making a rifle round? Personally, it’s crossed my mind a time or two, but I never put much thought to it. But in the video below, Larry Vickers and Sellier & Bellot’s Mike Fisher pull back the curtain and give us a glimpse of how it works.

A Major Production Facility

Mike runs the Sellier & Bellot facility in Vlasim, Czech Republic. The plant’s $200 million production shop turns out three million rounds of ammunition every day, producing everything in-house. They start with raw materials and turn out the finished product, including primers, in the same building.

S&B makes military and police ammo for 70 nations around the world as well as the civilian market. They generally produce 71 different calibers. The shipping department dispatches about 50 pallets of ammo every hour.

Twelve Step Process

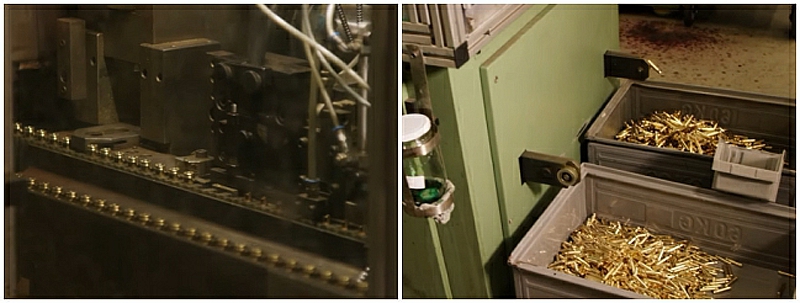

Sellier & Bellot starts the process with rolls of strip brass. The brass runs through a machine that punches it into cups for cases and jackets. The cups are then annealed so they can be worked without inducing stress. After the annealing process, the cups are pulled or drawn into what will become rifle or pistol cartridge cases.

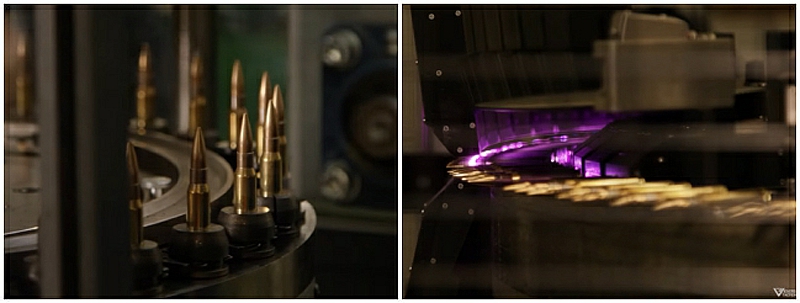

There are twelve steps from raw materials to final product. Sellier & Bellot’s machines can produce any centerfire rifle or pistol cartridge they need. Most of what we see in the video is 5.56 NATO ammunition.

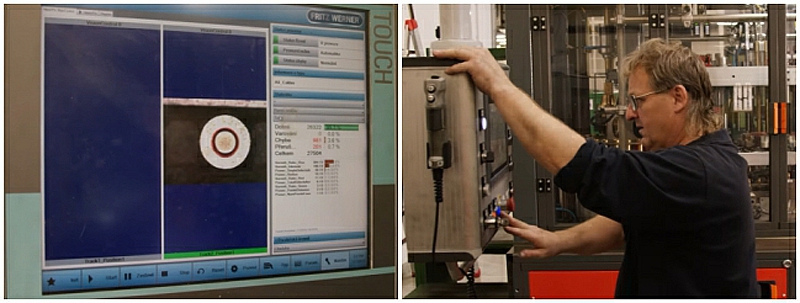

Mike says quality control is the most important part of the process. There are human and electronic quality control measures all along the line.

The brass cups go to the turning machine after being drawn. The turning machine cuts the extractor groove and trims the case to the initial overall length. We then see the transfer press which produces bullets for each cartridge.

Each case goes through an electronic inspection. Its dimensions must be perfect. If not, the machine pulls the case for recycling. The case is either perfect or it is not. There is no in-between.

Upon passing inspection, the parts come together for the loading stage. Primed cases enter the loading machine along with powder and projectiles. The machine combines the parts and turns them out at 160 rounds per minute. Mike shows Larry a machine working on 7.62×51 NATO cartridges. He notes that the same machine can and does produce other centerfire rifle rounds as well.

A Good Sign for the Ammo Market

All in all, it’s an interesting process. Of course, we can’t see the whole thing in a five-minute video, but it gives an idea of what ammo production entails.

Seeing Sellier & Bellot turn out three million rounds per day while maintaining a commitment to quality warms this gun guy’s heart. Here’s hoping other manufacturers are doing the same so we can keep those shelves stocked. Happy shooting, y’all.