I wanted to make an XM177-style AR-308 carbine as a big brother to my Blood Diamond gun, with modern specs in mind. Doing this meant I would have to overcome the obstacles presented by there being no standardized spec among AR-308s and join two separate specs into one functioning rifle. This AR-10A2 project was a fun one primarily for two reasons: I’d never seen anything like it before so I knew the end result was gonna be awesome, and I was told it couldn’t be done.

“Why can’t we make what we wanna make the way we wanna make it?! Why?!”

– Stanley Tucci, Transformers 4: Age of Extinction

One of the worst ways to discourage me from doing something is telling me it can’t be done because now I’m going to put all my energy into FINDING a way to get it done. It’s not out of spite, it’s just because I find the challenge intriguing — especially if nobody’s done it yet. Skunkworks projects like that are always fun.

Skunkworks Defined

[FYI: A skunkworks project is a project developed by a relatively small and loosely structured group of people who research and develop a project primarily for the sake of radical innovation. The term originated with Lockheed’s World War II Skunk Works project. Applied to firearms, it’s when a manufacturer does some unorthodox modifications or a series thereof to an existing firearm design, to adapt it for use in roles it wasn’t originally designed for, usually at the request of a government entity such as the US Military. Colt’s modifications to and experimentations with the AR-15 during and following the Vietnam War are an especially noteworthy example of skunkworks kind of stuff.]

Here’s What Sparked My AR-10A2 Carbine Revival Idea

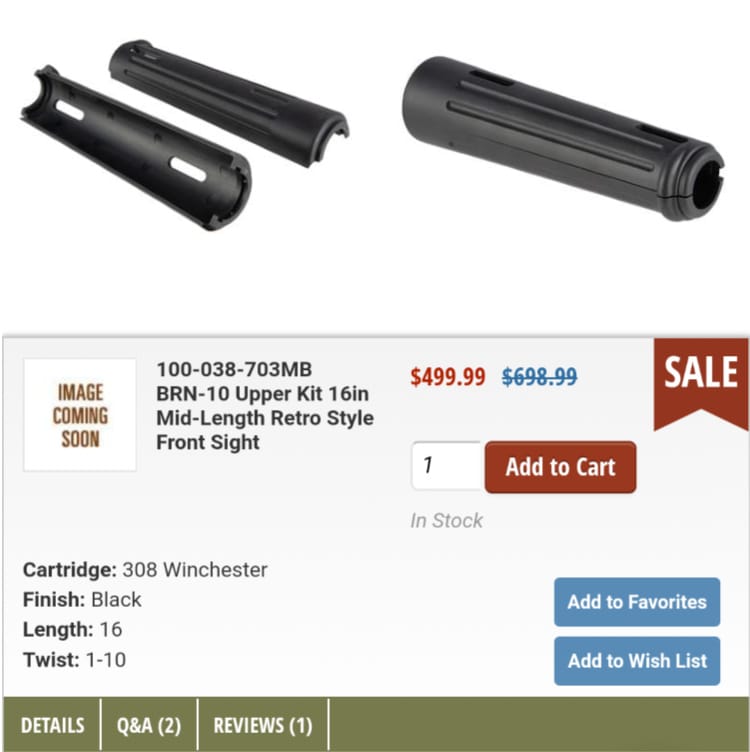

So there’s a little bit of backstory to this that needs to be covered before we get into the details of the rifle itself. Coming off my T46 BRN-10 project (which I just recently elaborated on) I noticed some parts listed on Brownells that didn’t seem like they fit into the equation. What I mean by this is, for a 20″ barreled rifle chambered in .308, why was there a midlength gas 16″ barrel available? Where were the handguards for it? Long story short, after talking with some friends at Brownells, it turns out that originally, not only was a Portuguese configuration BRN-10 on the to-do list but so too was a 16″ carbine version of the BRN-10 as well. It would have been modeled off of the actual carbine version of the Portuguese configuration AR-10, which was very rare compared to its 20″ barreled battle rifle counterpart.

Unfortunately, the Portuguese versions of the BRN-10, both rifle, and carbine, never came to fruition. It was deemed the juice wasn’t worth the squeeze. The complete factory guns were canceled. The parts for the carbine upper receiver group, rounded out by a set of midlength polymer handguards (which would have been used on both the Portuguese version rifle and carbine) were

available if you so chose to buy and assemble them. However, said handguards were only available in black, and without heat shields inside, with no plans for those to be produced either. So you could kind of get the carbine version of the BRN-10, but not the full effect. That was kind of a bummer since I had been playing with the idea of doing a carbine version build as a follow-up/hypothetical progression of my T46 build. But between no heat shields in the aesthetically correct handguards and no wood midlength handguard that I actually liked being available, I had discarded the idea of a BRN-10 carbine based T46 sequel.

But the idea of a fixed carry handle AR carbine chambered in .308 lingered still. It would be a few months until I revisited it with full attention, not until I started writing an alternate history timeline centered around the idea of the AR-10 winning the M14 trials and where US military small arms development would have gone from there. I had a mental image of where I originally wanted to go with

the BRN-10 carbine and used that as the starting point for this project. I was sitting there with this alternate history retro gun idea, and the more I pictured it the more I liked it. So I decide screw it, let’s run with it. I was thinking something like, what if the AR-10 carbine was adopted for the jungles of Vietnam? One of those 4x magnification carry handle mounted scopes like the ones Colt used to offer that Brownells reproduced for their Retro series sounded cool, in sort of a jungle DMR way.

“Carbine adapted for the jungles of Vietnam” brought the XM177-E1 & E2 to mind, and with it, my Blood Diamond clone, which was itself something of a splice between an XM177 and an Mk. 18 Mod. 0. So I started debating whether I wanted to do a full rifle-length stock like the Portuguese AR-10 carbine had, or an old-school collapsible carbine stock like the XM177’s.

I already knew what the Portuguese style carbine looked like, so I started looking up old pictures of the SR-25K. It was one of the earlier carbine versions of the rifle commercially available from Knights Armament during the time of the MK11 in the early 2000s. I knew it had the same looking stock that the XM177 had, along with a top rail-mounted carry handle and a fixed front sight. I wanted to remind myself of how those things looked on .308 sized receivers since it wasn’t very common. It worked, aesthetically speaking. It was a shorter, lighter, more maneuverable battle rifle.

That’s where the idea finally hit me: A .308 version of an XM177, or more accurately, my Blood Diamond gun. I’d never seen anything like it before, and the more I thought about it, the more I liked the idea. I knew the parts to do it right were out there, I just needed to get them all in one place and put them together.

Figuring Out All the Parts

My starting search criteria seemed simple at first: A fixed carry handle AR-308 upper receiver, and for both receivers to have angular receiver cuts not unlike those the Armalite AR-10 and its evolved form, the Knights Armament SR-25 (both initially developed and designed by Eugene Stoner himself) were known for. I wanted the fixed-carry handle for the retro vibe, and the angular receiver cuts because… I don’t know, it just would have felt wrong without them and using DPMS style curved cut receivers.

I started looking around, and after doing some research, it became evident that there was only one option that fit my criteria: the actual Armalite AR-10. Not the OG Sudanese/Transitional/Portuguese AR-10, but the commercialized AR-10 sold domestically by

Armalite that was very popular during the 90s. Once I came to understand this, I knew I was going to be entering some choppy waters. Because there is no de facto standardized spec/TDP among AR-308s, nothing among them between manufacturers is guaranteed to be so easily plug-and-play compatible the way it usually is for an AR-15 (barring certain exceptions like some billet receivers precluding the use of certain rails, and stuff like that).

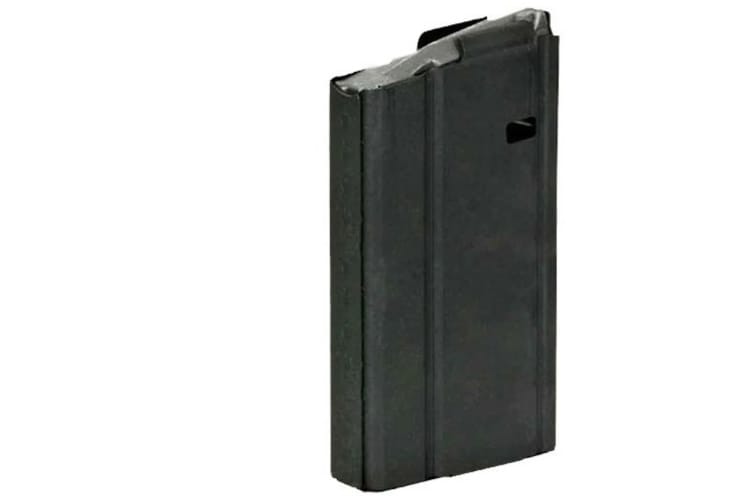

Mag Specs

However, I wasn’t intimidated, because Armalite had done a lot of the work for me already. With the advent of the Magpul PMAG 20 LR (and later PMAG 20 LR/SR), the .308/7.62×51 sized PMAG, a few short years later the industry decided that the SR-25/DPMS mag spec it followed would be THE mag spec for their AR-308 endeavors going forward, including any other firearms designs meant to feed from the same style magazine. This was because the .308 PMAGs were not only extremely well built but also just as cost-effective. It made sense for the industry to accommodate what easily became the go-to magazine pattern to enable the use of the most popular example of it.

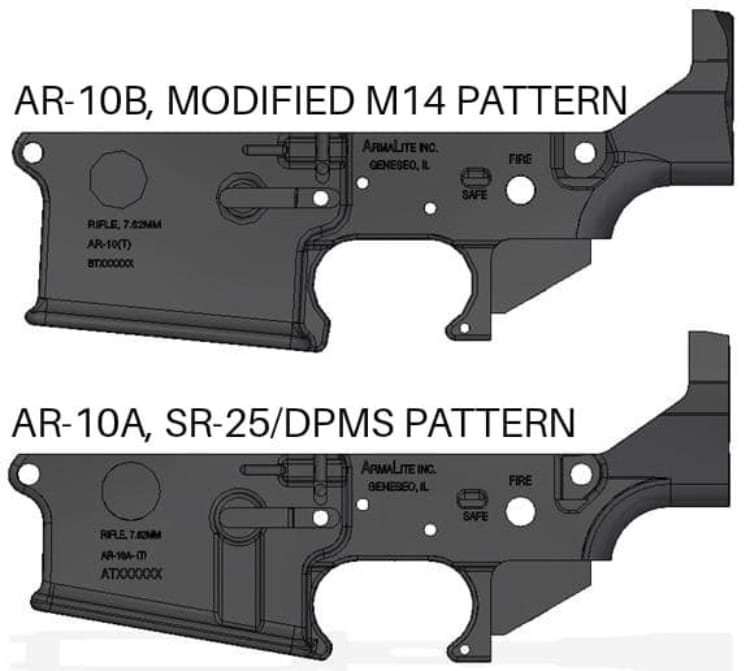

Up to that point, Armalite AR-10s had a proprietary magazine spec that was based around modified M14 magazines. The reason for this was that during the 1994-2004 Federal Assault Weapons Ban (AWB) in the United States, surplus (and therefore “pre-ban”) M14 magazines with capacities greater than 10 rounds were plentiful and easy to find, and with a simple modification that a mechanically inclined end user could make, they would now work in an Armalite AR-10. This spec is commonly referred to as “AR-10B” spec.

Confused About the Terms?

[Sidebar: I want to take a moment to explain some terminology I’ve been using that may have confused you: SR-25, DPMS, AR-10, and AR-308. What the hell am I talking about? Remember how I said there was no de-facto TDP spec among .308 ARs? All AR-10s and SR-25s are AR-308s, but not all AR-308s are AR-10s, SR-25s, or otherwise. The Armalite AR-10 is the AR-10, the KAC SR-25 is the SR-25, DPMS/LR-308 is a spec commonly used in the industry popularized by the former company known by the same name, that shares some metrics with the SR-25 spec because the SR-25 is the King that everyone else measures against and wants to be like.

There are AR-308s out there made by other manufacturers that are neither of those things, like the Brownells BRN-10 (DPMS spec + proprietary cut receivers,) the LWRC REPR (proprietary receivers and gas piston system), the SOLGW MK10 (another DPMS spec example), the Rock River Arms LAR-8 (proprietary receivers and mag well, uses FAL mags), the LaRue OBR, and others. AR-10 & SR-25 refers to specific specs and rifles by specific manufacturers, and ONLY those. AR-308 refers to ALL AR platform weapons chambered in 7.62×51/.308, regardless of the proprietary differences among them. You might see people or manufacturers loosely refer to an AR-308 as an AR-10 or SR-25, based on its cartridge/caliber or its magazine pattern. This is incorrect.]

So, if you tried to take an SR-25 spec magazine (even one of the original waffle type Armalite AR-10 mags from back in the day, which the SR-25 spec basically copied), and put it in an AR-10B, it wouldn’t work. The mag well would be too small, as it was made to accommodate the thinner M14 magazine body, and this continued in the upper receiver (which I’ll get to later).

Now, not long after the majority of the industry standardized its AR-308 mag well spec based around the SR-25 mag pattern to accommodate (and offer OEM) the .308 PMAG, Armalite saw the writing on the wall and decided to get with the times, kinda (I’ll explain later.) They ditched the proprietary modified M14 mag patterns and retooled their production lines so that now, the Armalite AR-10 was ALSO an SR-25 mag pattern weapon. This is referred to as “AR-10A” spec.

The Lower

So I knew, already sitting on a pile of the de facto standardized SR-25 pattern mags, that an AR-10A spec lower was what I needed (since I wasn’t about to introduce a proprietary magazine pattern for the same cartridge into my logistics chain). These lowers are current production and readily available stripped or complete by Armalite direct, so I ordered one complete.

Upper Receiver

In the meantime, I set out to find the upper. Knowing I was looking for an Armalite upper to match the receiver cuts with the lower, the Armalite AR-10A2 was brought to my attention. This was a 90s era AR-10B pattern rifle, having long since been discontinued by Armalite in the years since switching to flat top railed uppers and the AR- 10A spec. It’s exactly what it sounds like: an A2-style carry-handle upper receiver, only longer in .308 size. Of course, there were no comparable uppers made by other manufacturers laying around. That would’ve been too easy.

No big deal, I figured. I’d just peruse the used market and see what I could find. The AR-10A2 came in two forms: rifle and carbine. The latter was what I searched for, or at least, the upper for it. I didn’t need the lower since it was the wrong spec and I just ordered a new one. I planned on rebarreling the upper anyway, but I could reuse a lot of the stuff that came with it, namely the handguards, gas tube, and barrel nut assembly.

Stabilizer Shelves?

Around this point in time while I was asking for search leads to find this upper, having explained that I already purchased an AR-10A lower, a friend of mine that used to work for Armalite back when they transitioned from the AR-10B to AR-10A spec pops in and says, “Hey man, you can’t combine an AR-10B style upper with an AR-10A lower.” So I was like, “Well why the hell not?”

He tipped me off to something about the old AR-10B spec uppers I wasn’t aware of previously because I couldn’t see it. Inside the upper receiver, where normally there’s nothing but open space (like inside of an SR-25 upper receiver, let’s say,) there were these two flange-like shelves. The shelves came off the walls and front corners of the receiver just under the BCG track on either side of the barrel extension and protruded inward about a quarter of an inch or so.

The purpose of these unorthodox protrusions? They basically acted as stabilizers for the thinner modified M14 magazines I mentioned earlier. Their job was to prevent the magazine from rocking side to side within the upper receiver and therefore causing feed issues. Unlike the wider SR-25 spec magazines and AR-10 magazines of old from the 50s and 60s, the M14 mags weren’t as wide inside the receiver and therefore had wiggle room — more than a magazine usually does inside a rifle that’s made for it, anyway.

The problem these stabilizer shelves presented was that even though they were small, they acted as an obstacle. If you put an SR-25 spec magazine into an AR-10A spec lower alone, it’s fine. If you do it with an AR-10B upper attached, the magazine hits the stabilizer shelves on its way into the gun and can’t continue upward into the rifle far enough to engage the magazine catch. So I was looking at a picture of the AR-10A2 upper receiver interior and studying the stabilizer shelves. Inner me piped in: “Hey man. It’s just aluminum.” Oh yeah, good point inner me. We’ve cut into aluminum before. Back to my Armalite insider friend: “That’s it? That’s the only thing getting in the way here?” He said yeah. So I thought, “No problem, that’s nothing. I’ll take care of it.” Moving right along.

Found the Upper

I finally found someone selling an AR-10A2 Carbine on some old ghost town of a forum site. After some haggling, I talked him into splitting it and just selling me the upper. It wasn’t long before it arrived. It had a few light scratches on it, and the phosphate-coated 1/12 twist barrel with the blind pinned muzzle brake definitely showed its age and signs of the era from which it came. Those were of little concern to me since I was replacing those parts anyway. All that mattered was it was what I needed, an angular cut A2 style fixed-carry handle AR-308 upper, that came with the other parts I’d need anyway.

Takedown Pin Issues

I wanted something of a sneak preview of what to expect from the finished product, so between three AR-308s I had already (two SR-25s and a BRN-10), I figured I’d borrow one of their lowers and see how this new upper felt. This is where things started getting weird. On two out of three of the lowers, the rear takedown pin would close. On ALL of them, the front takedown pin wouldn’t close. On one of them, neither takedown pin would close.

I was perplexed, to say the least. The receiver cuts matched up on the two SR-25 lowers (and a small gap between the two when paired with the BRN-10 lower). Why wouldn’t the front takedown pins close? I’d read that the Armalite rifles were known for having proprietary parts in some respects (like the barrel nut for instance, which uses a different thread pitch than a DPMS spec barrel nut), but I never read anything about the takedown pins being different sizes. I hoped I wouldn’t need to bore out the upper’s takedown pin lugs to get the takedown pins on my new lower to fit.

When the Armalite lower arrived, I was actually impressed. Since the company name had changed hands multiple times over the years, and the quality output hit highs and lows over that time period, feedback regarding Armalite was a mixed bag. The lower I received came with an ambidextrous safety and a two-stage trigger that’s actually really nice to shoot. It also came with a Magpul MOE grip and STR stock, rather than some cheap throwaway stuff. Everything else on it looked fine, but I wasn’t worried about it anyway. I just wanted to make sure the damn takedown pins fit through the upper.

When I put the AR-10A2 Carbine upper on the AR-10A lower, I secured the rear takedown pin first because I’d had better luck with those on the other three lower receivers. It closed as expected. I put my hand on the front pin, gave a little “Please please please…” and a squeeze and it closed like normal with a staying satisfying click. Phew! Thus explains my earlier “kinda” about Armalite getting with the times when the AR-10A line came along: they’d updated the mag well spec and the uppers to accommodate it, but for whatever reason stuck with their smaller than usual takedown pin sizes.

Picking Out the Barrel, BCG, and Muzzle Device

So now that I had the upper and the lower, I needed to figure the rest of the new parts out. I knew I wanted a modern barrel with a 1/10 twist and nitride coating. In my research, I’d found that the Armalite BCG and barrel extension were also proprietary. However, testimony from others informed that you CAN rebarrel an Armalite upper with a DPMS spec barrel/barrel extension, as long as you paired it with a DPMS spec BCG (rather than just a bolt since they’d be incompatible with an Armalite spec bolt carrier.)

Remember what I said earlier about DPMS spec commonly being used in the industry for AR- 308s? Perfect example. The handguards that came on the upper were clearly midlength size, which therefore indicated to me that I’d need a midlength gas barrel. So I ordered a 16″ 1/10 twist, midlength gas, nitride-coated Modern Series barrel by Ballistic Advantage, and a Brownells BRN-10 BCG, both being DPMS spec. I also grabbed a new A2 front sight base tower, since the new barrel would need to be drilled and tapped for it and that requires a virgin barrel and FSB to be done properly. Seemed like an easy enough route so far, right?

I went with the 16″ midlength barrel to reuse the midlength CAR-15 style handguards that came on the upper, and so the gun wouldn’t beat the shit out of itself with a shorter 12.5″ barrel that used a carbine-length gas system. I also didn’t feel like SBR-ing the lower. There was also no adequate XM177 Moderator looking muzzle device that came in .308 bore or thread pitch to pair with such a short barrel, at least none that didn’t look weird or have something off about them. But I had another idea.

In light of the 16″ barrel, which also retained optimal ballistic performance for the .308 round, I decided to improvise for the muzzle device. Mainly for XM177-like aesthetics but also for function, I grabbed a slip over faux suppressor looking muzzle device that was ported at the end to provide a compensator function, made by Guntec USA. Altogether, with said muzzle device screwed onto the barrel, it looked perfect for that XM177 Moderator vibe on a .308, and the compensator ports added to that old school look for the retro feel I was going for.

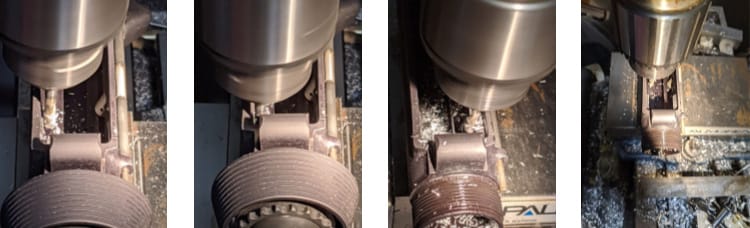

So now that I had all the parts I needed to rebarrel the upper. I took it all over to Dark Storm Industries, my local FFL with an in-house shop, where my friend Orion is the resident gunsmith. I got the upper stripped down on the front end, and Orion put the upper in the drill press to start milling out the stabilizer shelves. He then tapped the new A2 FSB on the bottom in the hole at the front sling loop so we could put a set screw to hold it in place since we didn’t have time to drill and install the taper pins proper that day.

Trouble With the Handguards

We got far enough to where we ought to be able to partially assemble the upper and test-fit the parts. We installed the barrel and barrel nut, slid on the gas block and handguard retainer cap, tightened the set screw, put the upper and lower together, and when we went to put the handguards back in place there was a problem. They were too long…? They wouldn’t fit in the space between the retainer cap and where they attach to the barrel nut and are held in place by the delta ring. What the hell was going on? Midlength gas barrel, midlength handguards… what wasn’t adding up? Orion looked at it and asked if they were the factory Armalite handguards, and I said, “Yeah.” He told me to try a different pair when I got home. Maybe these were a weird Armalite length and were too long to begin with.

When I bought the new furniture for the lower, I got an OD green CAR-15 stock, an OD green Brownells Retro A1 grip, and a brown BRN-10 grip, a set of OD green M4/oval style handguards in midlength, and the aforementioned black midlength BRN-10 carbine handguards. I got the green stuff since the AR-10A2 was originally offered with green furniture and I never had an AR with green furniture so I figured I’d check it out and see if I liked the Colt 605-ish color scheme. When they all arrived, the green parts were all a different shade of green, so that wasn’t happening. I uniformly coated them all in Earth Brown Aervoe spray paint and some matte clear coat. They looked sharp, but now my brown handguards didn’t fit onto the gun for some reason. So I figured I’d try the green ones and the black ones for good measure.

None of them fit. This was starting to get frustrating. All three were the same length, and we compared that measurement to that of other midlength handguards. All were the same length. What the hell was going on?! Why were midlength handguards not fitting onto a new midlength gas barrel? Was the delta ring too long? A comparison to the DPMS spec retro delta ring on my T46 BRN-10 said no. Was the Armalite spec barrel nut too long? A comparison to a DPMS spec barrel nut said no, they were externally the same size, the only difference between them being the thread pitch in the inside. So what was the problem?

Remember how I said earlier, there is no de facto TDP spec among AR-308s? A conversation with Marvin Pitts (of KAC dimpled barrel fame) revealed how deep the rabbit hole went. In AR-15 land, midlength is midlength is midlength. In AR-308 land, “midlength” is whatever the hell the manufacturer decides it is, so it’s not always the same between manufacturers.

As it turned out, there were two things going on here. For one, the Armalite barrel’s gas system length was longer than that of the Ballistic Advantage midlength barrel, which explained why the handguards didn’t have enough room to fit between the two points they needed to fit into. Second, and therefore obviously, the Ballistic Advantage barrel wasn’t made to use a delta ring, a front sight base with a retainer cap, and drop-in handguards. The only logical explanation was that it was made under the assumption that it would be fitted with a low profile gas block and ride under a free float rail. That meant it didn’t matter how many eighths of an inch longer or shorter the gas system was as long as it fit under said rail.

So I was a little annoyed at this point. The only way to mockup fit the gun together was to move the gas block forward of where it was supposed to be so the handguards could fit. I had a brand new barrel, that I paid for, that I couldn’t do anything with. I could reuse the factory Armalite barrel, but I really didn’t want to. What the hell could I do? Where could I find a newly manufactured barrel of the proper gas system length that’s Armalite spec compatible in an industry biased towards DPMS spec? Not from Armalite — the only applicable barrels as far as gas length goes were all pencil profile or too short and would have screwed with the muzzle device I picked out.

The Solution

The saving grace for this project came in the form of Ed, one of the owners of Dark Storm Industries and a good friend of mine. As I was venting about this issue that Orion and I couldn’t make heads or tails of, he hit me with the fact that the barrel I needed had been under my nose the whole time. When Ed and the gang over at DSI were first hashing out their DS-10 line and wanted to offer it in a “MOE” configuration that utilized drop-in handguards, they realized they had to go with the longer Armalite spec gas system length to facilitate the use of midlength handguards. So DSI’s .308 DS-10 barrels are Armalite spec gas system length, and therefore midlength handguard compatible, with a DPMS barrel extension. Just what I needed this whole time. Son of a bitch.

DSI’s DS-10 MOE rifle.I took my original Armalite barrel and compared it to one of the DS-10 hybrid spec barrels: the gas port, the gas block journal, shoulder, and barrel extension all looked like they lined right up. The only problem was, the DS-10 barrels only came in 18″ length. That was when Orion told me he had one that he cut down to 16″, rethreaded and recrowned. He said that he wasn’t doing anything with it, and he’d pull it from his upper for me. Right on.

I went over to his place and we hung out in the garage while piecing the upper together — this time with the 16″ DS-10 barrel. It was the moment of truth. Every component was where it needed to be, either torqued down or held in place via set screw. After looking at it all together, Orion turned to me with an enthused smile, “I think this is gonna work.”

He pulled back the delta ring, put the handguards in place, and let it go. Jackpot. In exchange for his 16″ DS-10 barrel, I gave him my 16″ Ballistic Advantage barrel and the midlength gas tube I had with it to put back on his upper. Since his upper had utilized a free float rail and a low profile gas block, the Ballistic Advantage barrel wouldn’t give him any compatibility issues. Fair trade.

Milling out the Stabilizer Shelves

So now that THAT was figured out, all that remained was to drill the front sight tower and barrel for taper pins, and finish milling out the stabilizer shelves (having run out of time and only partially finished doing so the first time.) After a few scheduling delays for which COVID-19 was to blame, we finally got time to use the shop over at Dark Storm to finish the job. The front sight install was now complete, and the stabilizer shelves were completely removed, allowing all the space needed for a variety of SR-25 spec mags to insert into the weapon completely. A little Aluminum Black where the stabilizer shelves were milled away covered up the exposed white aluminum and turned it black easy peasy, leaving no obvious signs of any machine work or modification. Orion oiled the BCG,

charging handle, and upper receiver interior before putting them back together.

Time to Testfire!

The last part was the fun part: Testfire. With the rifle now completely assembled and having about 3 mags worth of M80 ball to play with, we took it into Dark Storm’s indoor range to make sure everything jived. We put the target out to 7 yards, with the logic that a bullseye POA using the iron sights would result in a POI two inches below due to the mechanical offset, provided the front sight tower was properly installed with no cant to it.

Not only were the rounds hitting exactly where we expected them to, they did so without any feed or ejection issues. The revived AR-10A2 Carbine shot perfectly at varying rates of fire, with the recoil impulse of the slip over faux suppressor compensator comparable to that provided by an A2 birdcage flash suppressor. It felt and handled just like the battle rifle carbine it was intended to be. The mags inserted without issue when full, and ejected like normal when empty.

Our endeavor was a success! Orion and I shared a congratulatory fist bump. “Skunkworks as FUCK!” This was another “You can’t do that” defeated.

Fortune favors the bold.

Adding the Accessories

All that was left now was dressing it up with the rest of the accessories I had waiting for it at home. An A.R.M.S. #2 Extended carry handle rail mount served as the foundation for an Aimpoint PRO housed in an SRW-L ring mount (since the retro Colt-style 4x reproduction scopes are out of stock at Brownells). A spare M600U Surefire scout light mounted to a YHM rail riser was attached to a reproduction Surefire M10 barrel clamp mount that was shaved down to be routed through the space between the barrel and front sight tower, and secured at an offset angle. The Surefire ST07 tape switch was secured to the handguard via .gov issue green 100MPH tape. All just like the Blood Diamond carbine I had done late last year, concurrently with the T46 project.

When I put the Mean Gene Leather sling on the T46, I put its original Ranger Green Magpul MS1 sling on this rifle, so it had some jungle-tinted pop to it. The Earth Brown Aervoe, BRN-10 BCG, and Brownells repro AR-10 style grip were all selected as throwbacks/homages to the old school AR-10.

Since this was inspired by the XM177 and ended up being a fusion of sorts between that and an original M4, only in .308, it needed a name to reflect it.

I call this one XM762-E1. Since I reused the Blood Diamond carbine configuration as far as attachments go, I also nicknamed it BD² (Big Daddy Blood Diamond, Big Dick Blood Diamond, Blood Diamond 2: Judgement Day, whatever.) It is one of my most favorite rifles that I own — not only because of the effort that went into making it happen but because it’s light for what it is and there’s nothing else like it out there. The FAL and G3 style retro battle rifles can take a seat — XM762-E1’s got the rain blessing under control.

Skunkworks stuff like this is fun because of the challenge it presents. It’s the first step of innovation employed by many in the industry, and the motivating force to answering the questions “Can it be done?” and “Why not?” Some of the coolest stuff out there available to us now exists for two reasons: it had never been done before, and/or someone said it couldn’t be done. Either way, someone decided to roll up their sleeves and said, “Fuck that, let’s figure it out.” They got to work, and after some trial and error, they delivered.

Huge thanks to my friends Ed, Pete, and Kevin over at Dark Storm Industries, for designing the DS-10 barrel the way they did, and providing it and the use of their shop to execute this project. Extremely special thanks go to my friend Orion, who I couldn’t have done this without. He is a truly gifted machinist and gunsmith, and it shows in the approach he takes to his handiwork, the pride he takes in his craftsmanship, and the quality that comes as a result. Also thanks to Joe for bringing the AR-10A vs AR-10B incompatibility to my attention and walking me through that, Tim Orrock for helping me figure the name out, and to Minh, Cam and John, Trey Knight, Jack Leuba, Marvin Pitts, Frank Plumb, David Merrill, David Wilson, and Sam Glen, for their input, advice, and contributions along the way. You all helped me pull off another awesome project.

Moral of the Story

If you’ve got an idea in your head and you want to hold it in your hands, don’t let anyone stop you upfront by saying you can’t pull it off. Before you concede to that point, exhaust EVERY option and lead you come across. In the process, you might surprise yourself over who you know, what they know, and what you can collectively pull off when you put your minds to it. All it takes is a vision and a capability. The XM762-E1 is a lightweight example of that, compared to stuff some friends of mine have worked on, or are currently working on. Join us in being so daring and cavalier. In the meantime, stay safe, shoot straight, and make it count.