American military history is full of iconic firearms. As a nation founded by armed revolution, with the right to bear arms protected by our founding documents, it’s only natural that those weapons have carved out a niche in our story. Even many “non-gun” Americans are at least somewhat familiar with the Pennsylvania Rifle, Springfield rifled musket, Thompson submachine gun, M-1 Garand, and the M-16. Those of us more involved in the firearms world might add names like the M1903 Springfield, M1917 Enfield, M-1 Carbine, and Colt M1911.

Every one of those guns is a finely crafted firearm that served the country well on battlefields at home and around the world. Yes, even the M-16, once the early ‘60s misinformation was cleared up. But what if I told you that a crudely welded, stamped sheet-metal gun that was brought from drawing board to mass production in just nine months belongs on that list? In fact, that ugly but functional gun ranks just behind the 1911 and the M-16 family of firearms in length of US military service.

Of course, having presumably read the article’s title, you know I’m talking about the M3/M3A1 submachine gun. Commonly called the “Grease Gun” because it resembles the mechanic’s tool of the same name, the M3 first rolled off the production lines in May of 1943, seeing its first combat during the Normandy invasion a year later. By the end of World War II, the Grease Gun was firmly established as the front-line submachine gun of the US military, sending the Thompson to the sidelines, though that venerable firearm would occasionally pop up for the next 25 years or so.

The Demands of Global War

The Grease Gun was born from the demands of global war on a massive scale. By early 1942, the United States was fighting, or planning to fight, in Europe, Asia, and the Atlantic and Pacific Oceans. After the shock of France’s fall a year and a half before Pearl Harbor, the nation began mobilizing to meet the rising threat. A massive naval building program was initiated, along with increases in aircraft, tank, and general military production. The first-ever peacetime draft began the long process of building and training the force to fight the war that thundered on the horizon. By the spring of 1945, US combat units had deployed to five continents, and the US Navy all but owned the two largest oceans on the planet. American industry provided crucial supplies and equipment to China, the Soviet Union, the Free French, and the British Empire.

War on such a vast scale demanded unprecedented production of war material which, in turn, depended on finite resources. Maximizing those resources required efficient prioritizing and allocation of such things as steel, fuel, wood, rubber, and, not least, labor. Cost was also a major consideration, considering that all that stuff had to be paid for. Another oft-overlooked resource was machine tools. Any advanced manufacturing process demands them, and they can’t be produced overnight, considering they are often precision instruments constructed of top-quality components. All that and much more went into the making of the American war economy.

The Thompson: Iconic but Unaffordable

In light of all that, the standard US submachine gun, the M1928A1 Thompson, was a problem. The Thompson was a fine weapon crafted from forged steel with milled parts and nice wood furniture. In fact, it was over-engineered with a complicated locking system and a compensator on the muzzle. A pre-war Thompson cost around $200.00 to produce. That’s $4016.40 in 2022 money. With the rapid expansion that began in 1940, outfitting the troops with such guns was unsustainable.

The US Army Ordnance Department simplified the Thompson by axing the compensator and simplifying the locking system, resulting in the M1 version of the gun. The charging handle was also moved to the right side of the receiver from the top. The gun was simplified again with the M1A1 Thompson, which went to a fixed firing pin system. This reduced the cost of the gun to a more manageable 40 bucks per unit ($650 today). By way of comparison, an M-1 Garand cost about $85.00 ($1,381) to produce during this same period (I used 1943 for these numbers).

But cost wasn’t the only problem with the Thompson. Even the simplified versions required forged and milled components, along with the machine tools and the craftsmen to run them. Not to mention the time involved to turn out such a product. Those machine tools and craftsmen, and their time, were desperately needed for higher priority work. Recognizing that the Thompson had been simplified about as far as it could be, the Ordnance Department started looking for an alternative.

The M3 Grease Gun — It Ain’t Pretty but We Can Afford It

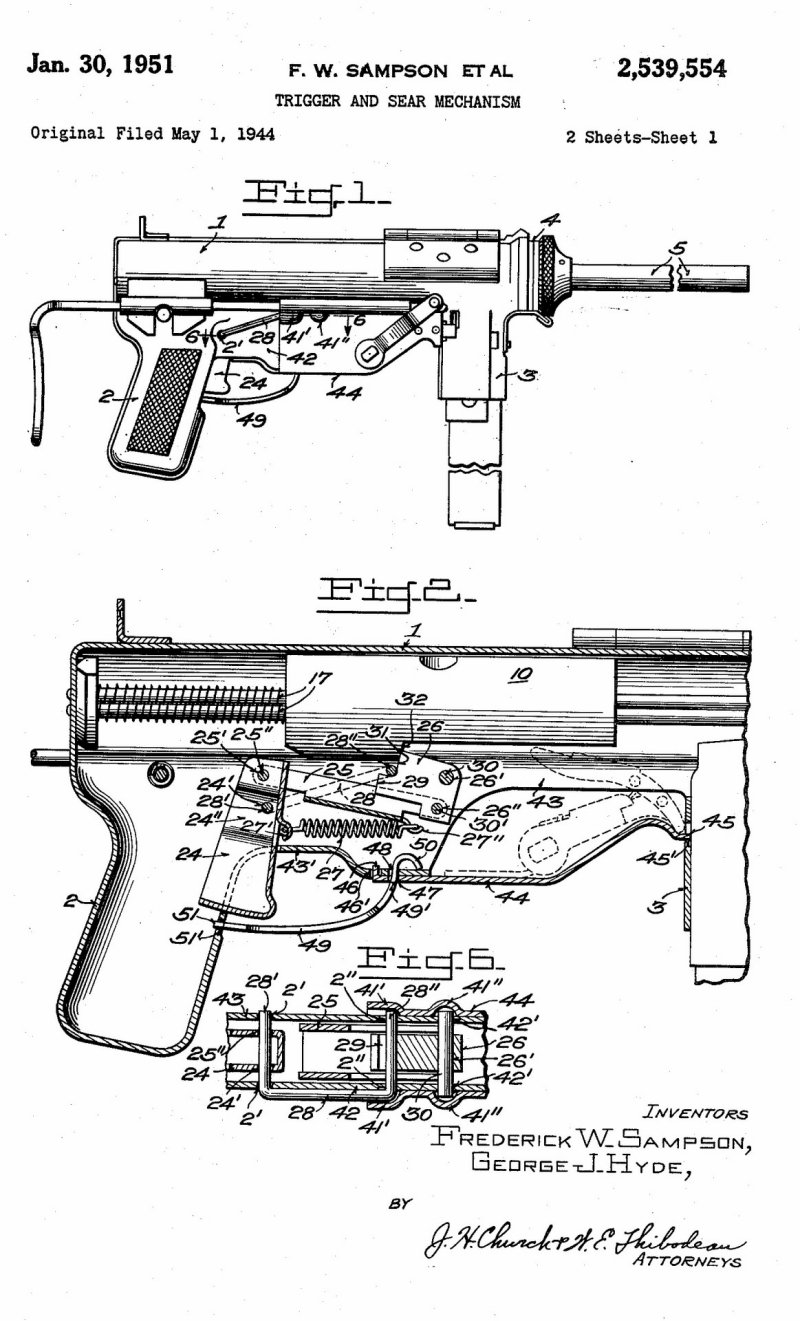

The department looked at several submissions for a low-cost submachine gun that could be mass-produced, and gun designer George Hyde was given the green light to produce a prototype in mid-1942. Frederick W. Sampson is also credited with the design, though his contribution seems to have been making certain the gun was suitable for the mass production techniques available at the time—an important aspect to be sure. These requirements were not unique to the United States. The British Sten, German MP40, and Soviet PPSh submachine guns were born of the same necessities.

The prototype was called the T-20 and underwent extensive trials at Aberdeen Proving Ground through the fall. Records show the T-20 performing better in the mud and sand tests than any other American submachine gun ever tested. That performance was due to the fully enclosed operating system that kept out foreign material combined with generous tolerances to allow operation in extreme conditions.

The T-20 was recommended for adoption in December, with final approval coming on 11 January 1943. The contract for the new “U.S. Submachine Gun, Caliber .45, M3” was awarded to General Motors’ Guide Lamp Division. Guide Lamp, having extensive experience working with stamped steel components, and the presses to do it on a large scale, was the perfect choice. It was also the industrial concern for which Sampson tailored the M3’s design, so that worked out pretty well. As noted firearms historian Bruce Canfield points out, such industries were underused at that point in the war. Making M3 submachine guns was a way to put that capability to good use. The only machining done by Guide Lamp was the cold swaged rifled barrel. The one component not made at Guide Lamp was the machined bolt, which was contracted to the Buffalo Arms Company. After tooling up, the first production M3s were delivered in May.

They weren’t pretty. The receiver was made of two stamped sides welded together. The welding was functional, if sloppy looking to the modern eye, with no real attempt at making the gun aesthetically pleasing. The important thing was that it was economical, and it worked. The cost per finished unit was $20.94 ($340.30 today), roughly half the cost of a Thompson M1A1.

The M3 was economical in other ways too. Compared to the Thompson, it cut the man-hours to produce it in half and the required machine tools were reduced by 25 percent. So, essentially, twice as many M3s could be produced for about the same cost compared to the Thompson, with a significant reduction in machine tool requirements, in the same amount of time. When you’re producing hundreds of thousands of guns in a stressed war economy, that’s kind of a big deal.

The Grease Gun — Hey, it Works!

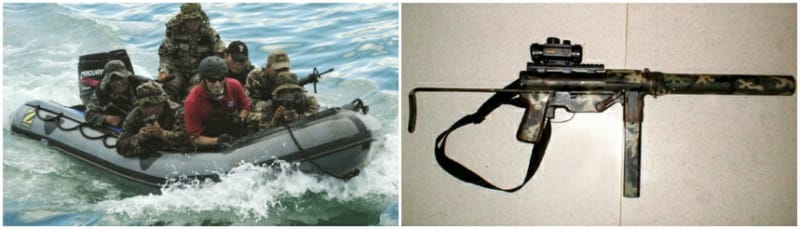

Quickly dubbed the “Grease Gun” because of its appearance, the M3’s development had drawn the interest of the Army’s Infantry Board, Armored Forces Board, and Airborne Command. Not only was it inexpensive and reliable, the M3 weighed only eight pounds, a full four pounds lighter than the Thompson. Its collapsible wire stock and eight-inch barrel also made it more compact. The advantages were apparent across the board. The lighter, more compact weapon was perfect for tank crewmen and airborne troops alike, not to mention the infantrymen who had to hump the gun across Europe. It held similar advantages for amphibious troops too, especially with its resistance to the negative effects of sand and volcanic dust.

Not surprisingly, given its appearance, the troops didn’t like the Grease Gun at first. After all, their trusty Thompsons had served them well. It took time and experience to recognize the rugged reliability of the new gun, as well as the advantages it offered over the Thompson. Besides size and weight, the Grease Gun was easy to disassemble and maintain. It had few moving parts and the removable wire stock doubled as a cleaning rod.

As with any new service weapon, especially one rushed to production as the M3 was, a few problems surfaced in the field. To the designer’s credit, though, most were minor. The most serious issue was the inferior steel used to produce the charging lever. If the gun was knocked around or dropped on its right side, the lever could, and often did, break off, rendering the gun inoperable. With replacement parts for the new gun still in short supply, Army ordnance units developed a simple but effective field expedient. A slot was cut into the top of the receiver at the two o’clock position and a crude charging handle attached directly to the bolt. The soldier could then pull back on the charging handle, which traveled through the slot, to cock the gun. There is some evidence that this expedient was confined to the US Third Army, but either way, it was a fairly common and ingenious fix that kept the M3 running.

The Cheap Date Turns Out to be Marriage Material

The Ordnance Department began looking at upgrades to the M3 in April 1944. The charging lever was dumped in favor of a finger hole machined directly into the bolt to cock the gun. This necessitated a larger ejection port, but that was no big deal. A sturdier rear sight was added along with a magazine loader attached to the stock. The barrel nut was cut to allow the wire stock to be used as a wrench when the gun was disassembled. The oil bottle was moved from its left side attachment to inside the pistol grip. Upon its acceptance in January 1945, the new M3A1 became the standard-issue American submachine gun, though the M3 was kept in service with the designation “Limited Standard.” All that meant was that M3s would still be used, but all new production guns would be M3A1s. As it turned out, the vast majority of Grease Guns were the original M3 models. The war ended eight months after the adoption of the M3A1 so most never made it to the combat units. January also saw the recommendation that all Thompsons be phased out in favor of the Grease Gun, but that goal was not reached during the war and a few Thompsons remained in the US inventory until the late 1950s. I’m told by some veterans that the Thompson made an occasional appearance in Vietnam as well.

Production of the Grease Gun was cut at war’s end and the final numbers were 606,694 M3s and 15,469 M3A1s made during the war. The gun served well in Korea and a contract was let to the Ithaca Gun Company in 1954 for 70,000 M3A1s to replace the inventory lost over the previous three years. Manufacturing got underway in 1955, but the need for the guns had passed and production was stopped at 33,227. All told, the United States produced 655,390 Grease Guns, of which only 48,696 were the updated M3A1. There’s no way to know how many of the original M3s were modified in the field but they can occasionally be found.

The Grease Gun continued in US front-line service into the early Vietnam years and was supplied to indigenous allies in Southeast Asia in large numbers. A suppressed version was carried by some US Army Delta operators on the ill-fated Operation Eagle Claw in Iran in 1980. The gun remained a mainstay with US armored forces and truck drivers through the first Gulf War before being “retired” in 1992. Some Grease Guns reportedly saw service in Iraq and Afghanistan as part of the Global War on Terror and are still used by several nations around the world. Not bad for a contingency-based gun that was slapped together as quickly and cheaply as possible during a global emergency. I’d say George Hyde and Frederick Sampson done good.