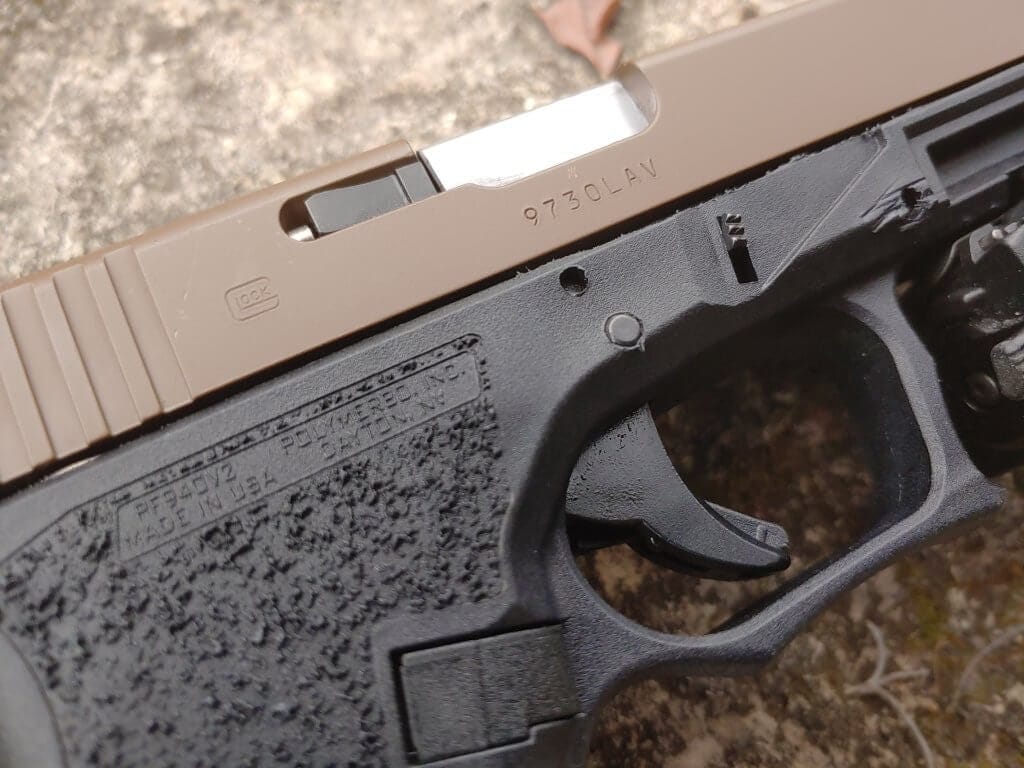

I built a Glock! Kind of. I slightly milled the frame of what would become a Glock. I basically Dremeled and filed away at some polymer until a slide and lower components fit. It’s not exactly complicated but admittedly I felt pretty accomplished by the time I got it firing reliably. The Polymer 80 isn’t considered a firearm when you purchase it. You can literally buy it on Amazon and have it shipped to your home. Some states have crazy laws regarding serializing firearms you’ve constructed but most do not. The Polymer 80 frame isn’t necessarily based off an actual Glock frame, but it works with Glock parts. Polymer 80 PF940V2 has made a few adjustments to the design.

Most notably they’ve changed the grip ergonomics a good deal. There are no finger grooves and the Polymer 80 frame’s grip angle is a 1911ish 18 degrees versus the standard Glock 22 degrees. The gun even sports a full length Picatinny rail.

The rear of the frame also features what’s not quite a beavertail (but it is longer than a standard Glock frame). This is the standard full-size Glock 17 frame, but they also offer 26, 19, and hybrid frames that have Glock 17 slides on Glock 19 grips. These frames are designed to work with Gen 3 parts.

Building it Out

I don’t want to go too deep into the build process, or the milling process. Milling the Polymer 80 is very easy to do, I used nothing but a dremel and handgun drill. Of course, Polymer 80 provides the jig and drill bits needed to finish the gun. I also used a small file to hand fit the slide to the frame.

I used a Gen 3 Glock 17 slide that appears to be an overrun of a Larry Vickers edition. It’s FDE and sports Ameriglo sights. The barrel is something I’ve had laying around for quite some time and I’m not exactly sure who makes it. There are no markings besides caliber and model number. It was given to me. It’s a stainless steel threaded barrel and it fits and functions without effort.

The gun uses OEM parts for the lower, outside of the included rails from Polymer 80. I am using an extended magazine release and extended slide lock. Installing parts into a Glock is incredibly easy, way easier than even an AR 15. To be clear, building a Polymer 80 is very simple and easy to do.

Range Time With the Polymer 80

Hitting the range was a hit or miss thing with the Polymer 80. The first few times I went to the range, I would have malfunctions, come back home, file a bit and hit the range again. I also read on several forums that you have to cycle the slide upwards of a few hundred times before it fires reliably. I certainly did that during filing.

I always call bullshit at the idea of breaking in a new gun in. It’s 2019 and modern manufacturing should be precise. However, I am in no way a modern manufacturer. My gun required a break in period and I loaded up three ETS 31 round magazines to get it done. After each magazine, the gun got a little better. I had plenty of little failures to extract and eject along the way.

The pattern went like this: shoot a magazine of ammo, do some filing, add some oil, shoot another magazine…. I was quite elated the first time I ran through a full magazine without issue. After that, the gun ran like a champ. It did take about a 150 rounds to break in, but it runs reliably now.

Accuracy and Reliability

The frame to slide fit must have not been too sloppy since the gun is exceptionally accurate. The barrel features traditional rifling versus polygonal, but it seems to get the job done. The Ameriglo sights are very nice overall. I’ve been ringing steel back as far as fifty yards on my favorite little popper.

As a full sized 9mm handgun you don’t expect much recoil and you don’t get much either. The small beavertail does add a little rear leverage to hold the gun down and increase your control. Firing fast and accurately is easily achievable. I might go full-bore and toss on a comp since I’m already running a threaded barrel.

As I mentioned previously there were some initial issues until things started running smoothly. A gun I built myself isn’t my go-to for serious use, but I do want it to run. I’ve seemed to overcome some real issues with reliability.

I also wanted to ensure magazine compatibility. What’s the point of a Glock wannabe if it doesn’t reliably use Glock magazines? I tested it with the above mentioned ETS magazines, Magpul Glock Magazines, KCI Glock magazines, and of course the OEM magazines. They all run reliably and zero issues when it comes to insertion and ejection. The same goes for feeding rounds into the gun.

Let’s Talk Ergos

Ergonomically, I really love this gun. Grip angle is fantastic and the lack of finger grooves is a big deal to me. It’s a wide grip, but I have big hands and I love it. The extended magazine release and slide lock are very nice. Like all Glocks, my fat thumbs hold the slide lock down so the slide doesn’t lock open when the weapon is empty.

The Polymer 80 has a deeper cut under the trigger guard which allows you to hold the gun higher and exert more control. Additionally, the magazine release has an excellent relief cut and this makes the magazine release likely easier to reach than a standard Glock magazine release.

Overall, I prefer the ergonomics of the Polymer 80 frame to a standard Glock. Even the compared to the new Gen 5 I prefer the Polymer 80 frame. The grip angle is much better and feels more natural to me. This is subjective, and if you prefer the standard grip that’s understandable.

Overall it just feels less like a brick in the hand and more like a gun.

A Blank Canvas

One of the coolest features is the fact that the Polymer 80 is a blank canvas. The Glock has a massive aftermarket and you can start at ground one and build the gun you want with the trigger, controls, slide, sights, and barrel you want.

The only downside is I found that the P80 wouldn’t fit a few of the holsters I have for my classic Glock 17, however, others fit perfectly fine. This is certainly something you need to investigate prior to purchasing a holster.

The Glock Gen 3 has a very wide amount of aftermarket slides and they seem to be the more popular of slide options. The Polymer 80 PF940V2 is quite customizable and you can dig deep into making this the gun you want it to be. It’s one of the most fun projects I’ve done in some time, and I can’t wait to build another.

Happy to hear about the issues you had, but only because i can tell a fellow shooter who just completed one and is having the same issues as you did. he’s young and inexperienced but will be happy to hear it probably just needs to get broke in.

I have done a few, they take some wearing in. I over oiled mine and blew a few hundred rounds through them, after that they are Golden!

Thanks Aaron

I enjoyed the article, very informative. I’m not a glock guy ( but I have done some glock mod’s on a neighbors G17 ). I’m a 1911 & AR guy, I have done several 80% AR lowers and like “making” my own. but I always tell people that the best gun is the one that suits your needs and is one that you can shoot accurately and comfortably, we all have different needs and in different environments.

I have built a few of these Poly 80s. The slide to frame fit issue is easily resolved. I use valve lapping compound on the rails. Strip the slide and the frame keeping the pins in that hold the rails together. Plug the firing pin channel with cotton or paper towels…make sure you can get it out easily! Keeps the grit from fouling the sensitive areas. Apply a little lapping compound to the rails, put on the slide and work it back and forth until it cycles smoothly. Clean everything good with alcohol and reassemble and oil. A couple tries should have you in the sweet spot. Filing the rails makes the frame to slide fit hit and miss…usually uneven. Lapping is how pistolsmiths do it….ala 1911 builders. I was lucky to have been able to work with a master gunsmith for a year and learned a lot from him. My P80s are tight yet smooth and reliable!

It is a nice feeling when you complete a P80 and get it running good, my g19 came out best shooter from bullet one, and the only one with an aftermarket slide, go figure.

Body armor has proven that it dramatically decreases the wearer’s chances of death. And this is the valid reason that has led lawmakers to regulate the purchase of bullet proof jackets it so that criminals do not get the protection it provides.

What does this have to do with Polymer80 Glocks? Additionally, I disagree that regulating body armor is a valid reason. Criminals will still obtain it, but law abiding folks will have a harder go at it, unfortunately. Everyone should have access to body armor, even if they aren’t interested in owning a firearm.